Our custom edging and beveling services are offered in a variety of styles and thicknesses to transform your piece of glass into an art form. Whether you’re looking for a bevel, bullnose, triple waterfall, or V-groove, we can create the type of edging you desire for your glass piece. We can cut glass for mirrors, glass tabletops, cabinets, showers, windows, and doors – there’s no project too big or complex for our team. Whether your job requires an oval, large square, or a custom piece, our highly trained glass and mirror cutting professionals can deliver. Whatever style and shape of glass you desire, we can cut it for you. Our glass and mirror cutting services are done right here in-house to ensure that you get the perfect shape every time. You can also add a small amount of soapy water to the plexiglass surface for additional lubrication while cutting.Looking for a unique shape or textured piece of glass to add to your space? M&T Glass can help you get the right size and shape cut to fit. Leaving the thin plastic film on the surface acts as a lubricant to an extent, but if your blade starts to overheat, pause and turn off the saw to let it cool.

#CUSTEM CUT FLEXIGLASS CRACK#

As mentioned earlier, an overheated blade on a power saw can also cause plexiglass to crack and break during the cutting process. A dull blade will fight against the material, potentially causing cracks and breaks-not to mention an overly rough cut edge. Whether using a hand tool or a power saw to cut plexiglass, it’s important to use a sharp blade. When using a knife such as a box cutter to cut plexiglass, be sure to score a straight, deep line before attempting to break the material at the mark. Leaving that film on as you measure, mark, and cut will prevent scratches from your tools and work surfaces. As mentioned above, plexiglass usually comes with a thin layer of plastic film intended to prevent scratches as the material travels from manufacturer to retailer to your workshop.

#CUSTEM CUT FLEXIGLASS HOW TO#

Keep the following tips in mind when learning how to cut plexiglass to prevent irreversible damages.

Though plexiglass is a durable material, it’s not unbreakable. Tips to Avoid Cracking or Breaking Plexiglass as You Cut Outfit your electric drill with a buffing pad and, after applying a polishing compound formulated for plastic, bring the plexiglass edge to a perfect polish.

#CUSTEM CUT FLEXIGLASS MANUAL#

Note: You can use a handheld power sander, but manual wet-sanding typically achieves the best results. If the cut edge would be visible in your application, take the extra time to sand and buff out the imperfections. Whichever cutting method you choose, you may find that the cut plexiglass edge doesn’t look terribly attractive. How to Cut a Thin Sheet of Plexiglass (with a Utility Knife, Box Cutter, or Glass Cutter)įor a thin sheet of plexiglass-that is, material up to about 3/16-inch thick-use a scoring method not dissimilar from a technique used to cut actual glass. Simply cutting plexiglass to size is easy by comparison.Ĭontinue reading for details on how to cut plexiglass-the right way. If your project requires a clean edge, expect to devote energy to smoothing the finish. Second, bear in mind that even if you’re careful, it can be difficult to cut plexiglass without leaving a rough, irregular edge. When cutting plexiglass, leave the film in place as long as possible to avoid marring the surface. The other downside? Homeowners who don’t know how to cut plexiglass can be intimidated by the material at first-but we’re here to help! That’s why sheets of the material come covered in a thin layer of protective film. Versatile and tough though it may be, plexiglass isn’t perfect.

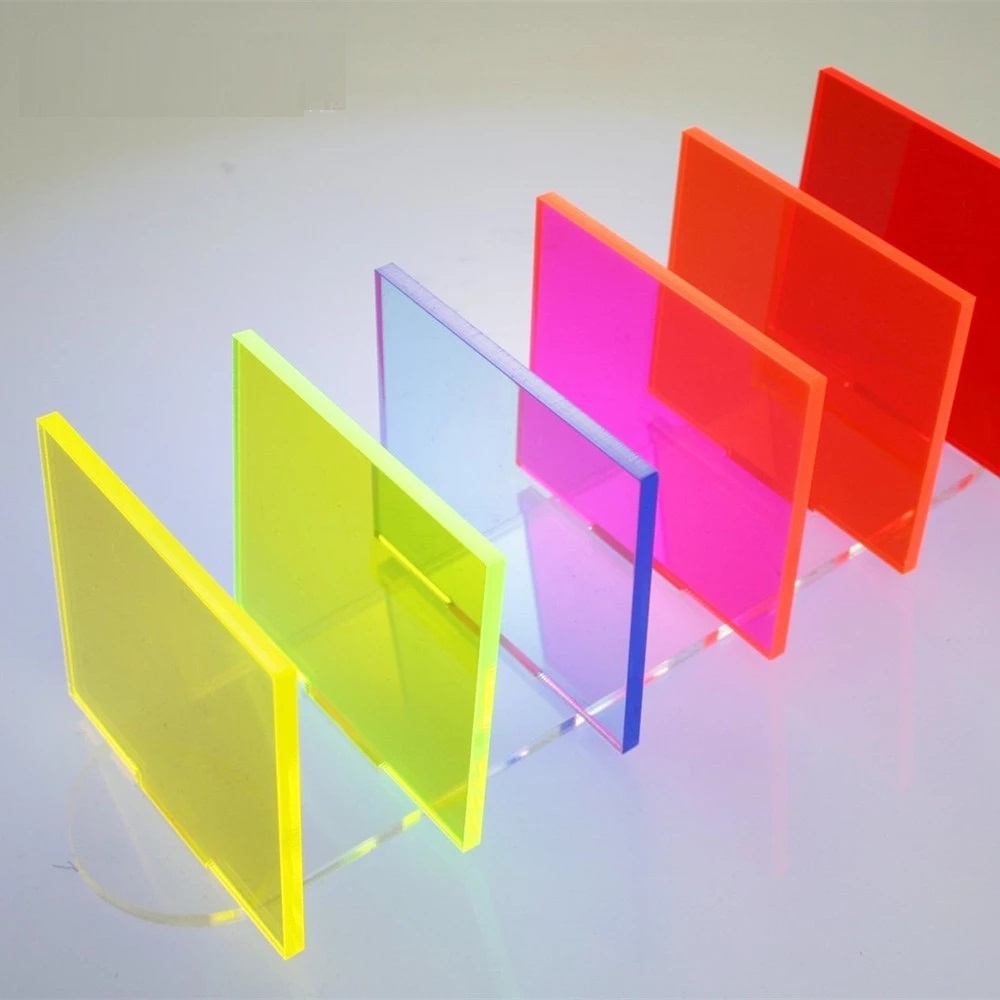

In fact, due to its light weight and durability, many do-it-yourselfers prefer plexiglass, not least because it can be cut and shaped with common workshop tools. In a range of applications, from picture frames to tabletops, plexiglass (also known as acrylic) serves as a cost-effective, shatterproof substitute for glass.

0 kommentar(er)

0 kommentar(er)